DLP (Digital Light Processing) is a similar process to stereolithography from the perspective that it concerns a 3D printing process that works with photopolymers. The major difference, however, is the light source used to cure the resin. DLP uses a more conventional light source, such as an arc lamp with a liquid crystal display panel, which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SL.

“Additive manufacturing method in which a moving DLP projector and mirror is used to solidify a liquid polymer layer by layer”

Also like Stereolithography, DLP produces highly accurate parts with excellent resolution, but its similarities also include the same requirements for support structures and post-curing. One great advantage of DLP over SL is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

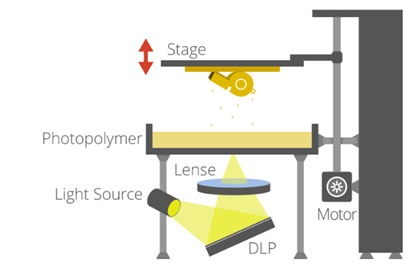

DLP – How it Works

Here is an explanation of how it works:

The DLP Process in a Nutshell

In this process, once the 3D model is sent to the printer, a vat of liquid polymer is exposed to light from a DLP projector under safelight conditions. The DLP projector displays the image of the 3D model onto the liquid polymer. The exposed liquid polymer hardens and the build plate moves down and the liquid polymer is once more exposed to light. The process is repeated until the 3D model is complete and the vat is drained of liquid, revealing the solidified model. DLP 3D printing is faster and can print objects with a higher resolution.

Post Processing and Support

Because of the nature of the SL process, it requires support structures for some parts, specifically those with overhangs or undercuts. These structures need to be manually removed. In terms of other post processing steps, many objects 3D printed using SL need to be cleaned and cured. Curing involves subjecting the part to intense light in an oven-like machine to fully harden the resin.