Partnership Luximprint and SilvaCo Optics Take Printed Optics to Silicon Valley

Luximprint, a leader in offering multi-market prototyping services for Printed Optics and Optographix based in The Netherlands and SilvaCo Optics, a renowned California based optics, sensors and components consulting practice announced this week the partnership they entered into for marketing Luximprint solutions in California. An interesting move that makes access to rapid prototyping services for custom optics easier in the Silicon Valley surroundings. Here’s the latest.

Printed LED Optics – Fast, Flexible and Cost-Effective

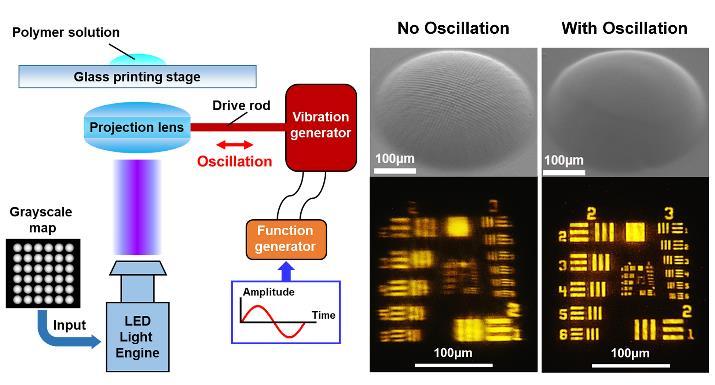

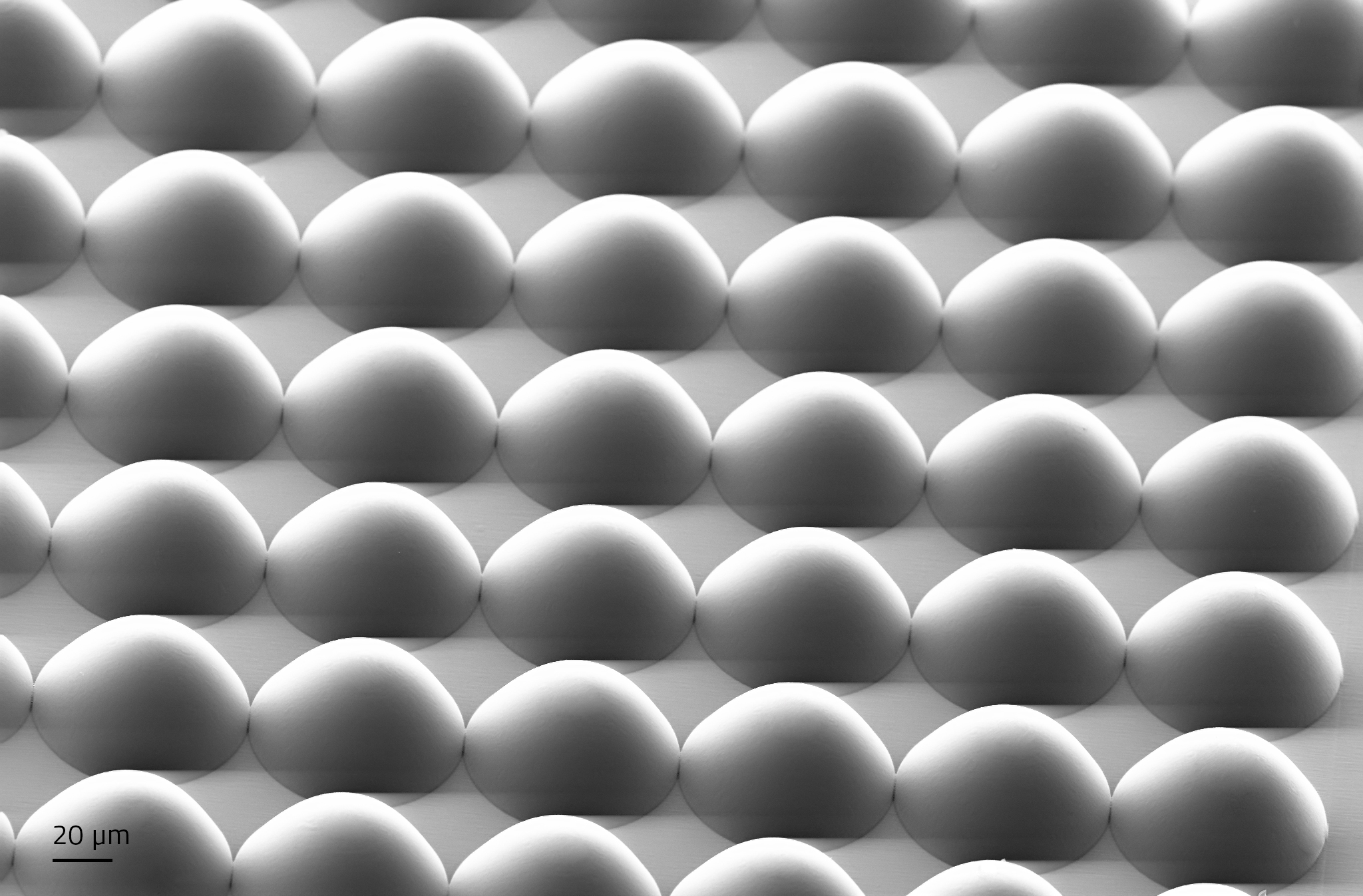

Rapid prototyping services for custom optics are an interesting approach for designers and engineers working with light. Thanks to the optical 3D printing process, a proprietary solution by Luximprint to generate custom optics, tailored parts are available in days, which enables a fast, flexible and cost-effective engineering job when it comes to the development and implementation of new high tech systems in multi-market applications.

The direct ‘CAD-to-Optic’ manufacturing process from Luximprint grows optical clarity parts additively, aiming to offer a novel approach to validate optics designs, justify mold-tooling investments, as well as to create inspirational and functional mock-ups for event and user demonstration.

Printed Optics Come to Sillicon Valley

By having SilvaCo appointed as a local sales agent, needs centering around optics and photonics applications can now easily be addressed, just in time. Peter Silva, Principal of SilvaCo, was raised and educated in Silicon Valley when the South Bay was more orchards than manufacturing and before there was high tech. SilvaCo will work diligently to help find a solution that can satisfy customers that are in search of fast, flexible and cost-effective solutions in custom optics and other 3D printed solutions as marketed by Luximprint.

Custom Optics in Days by SilvaCo Optics

Companies located at the US West Coast in search of rapid prototyping custom optics solutions are encouraged to contact SilvaCo to discuss their next projects and utilize the powerful benefits of optical 3D printing. With typical lead times of 5-10 business days and global delivery with local support, rapid availability of custom optics is now guaranteed!